Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Corrugated Line

Brand: LLY PACK

Applicable Industry: Manufacturing Plant, Other

Out-of-warranty Service: Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Status: New

Application: Machinery &Amp; Hardware

Type Of Packaging: Cartons, Case

Packaging Materials: Paper

Degree Of Automation: Automatic

Power Type: Mechanical

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: High-Accuracy, Sustainable, High Safety Level, Easy To Operate, Remote Monitoring, Flexible Manufacturing, Low Noise Level, Competitive Price, Energy Saving, High Rigidity, Long Service Life, Automatic, High Productivity, Multifunctional

Marketing Type: New Product 2020, Hot Product 2019, Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Gearbox, Motor, Bearing, Engine, Pump, Plc, Other, Pressure Vessel, Gear

Certification: Ce

Warranty: 1 Year

Condition: New

Automation: Automatic

Service: 24 Hours Online

Origin: Guangdong, China

OEM: Provide

Trademark: Lly Pack

Transport Package: Plastic Film And Wooden Box

Model NO.: 2800mm

Paper Thickness: Normal Specification Paper

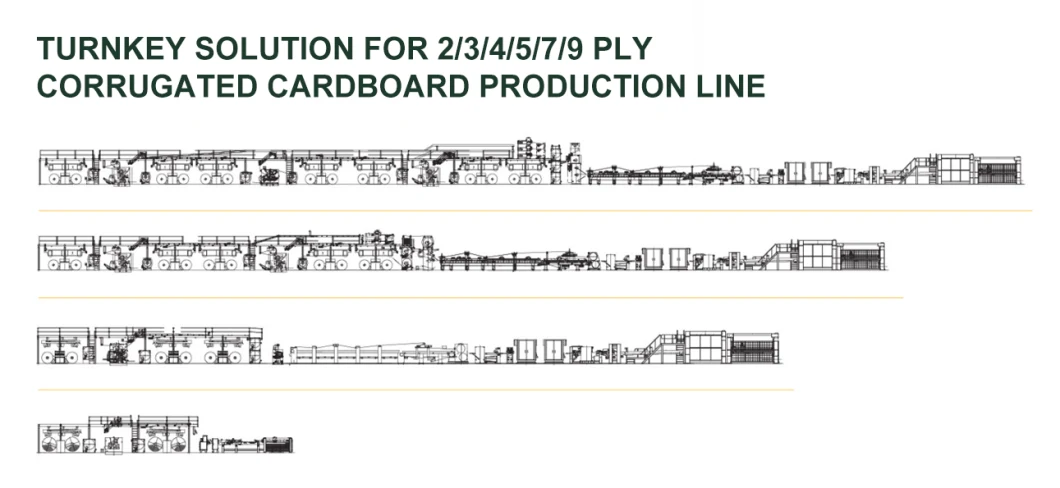

Product Name: 2/3/5/7/9 Ply Corrugated Cardboard Production Line

Speed: 100-330m/Min

Max Paper Size: 2800mm

Heating Way: Steam Heating

Steam Pressure: 10 Kg/Cm2

Required Power: 255/355 Kw, According To The Speed And Machine

Boiler: 2, 3, 4 Mt/H, According To The Line Speed

KEYWORDS: Corrugated Cardboard Making Machine

Advantage: 22 Years Experience In Corrugated Indusrtry

Specification: 2800mm

HS Code: 8441309000

After-sales Service: Field Installation, Commissioning

Suitable For: Paper

Packaging: Case

Productivity: 50 set/years

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 50sets/Year

Certificate: CE.ISO.TUV.SGS

HS Code: 8441

Port: Foshan,Guangzhou,Shenzhen

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,CFR,CIF,EXW,FCA

Automatic 3 ply corrugated carton production line

Product Description

Pit machine fully closed wallboard, high thickness casting base, large area positioning surface structure, large and small roll structure, oblique low center of gravity design, flip paste seat structure.

The soft contact structure of pressure roll and paste roll of pit machine is easy to adjust.

Double-sided stacked structure, three-point support structure, split drive main drive.

Pit machine cavity tube core paper, pit arc plate, peripheral heating corrugated roller, cavity tube hot cylinder, double-sided cavity tube inlet arc plate, cavity tube hot plate, steam spray hot plate.

Pit machine 4 groups of proportional valve control, double-sided machine four groups of proportional valve control, steam pressure fine regulation, production line steam secondary utilization, return water pressure back to the boiler to achieve the third utilization of steam. Realize the efficient utilization of steam system.

The high efficiency transmission chain design, such as direct connection, synchronous belt, precision gear and bevel gear, is adopted to realize the high efficiency and energy saving of the transmission system, such as energy saving and high efficiency motor, closed loop vector frequency conversion drive and so on.

The high precision structure of glue gap, the precision adjustment of gap in electric cylinder transmission, the slurry supply system of diaphragm pump and the automatic feeding system can realize the efficient and non-destructive transportation of glue. The pit machine is standardized with a water cooler to cool the hydraulic system and reduce the temperature of the pulp basin at the same time, so as to prevent a large amount of condensation of glue at low gelatinization temperature.

A Complete Corrugating Board Production Line Includes The Following Machines:

Corrugated Cardboard Production Line for Carton

| 1,Maximum mechanical speed:300m/min |

| 2,Production line width:1400~2800mm |

| 3,Positive pressure cassette type quick roll change single face corrugator |

| 4,Double motor upper and lower independent drive double-sided machine |

| 5,Equipment high stability, low noise, long life |

| 6,High physical index and high speed of cardboard |

| 7,Energy saving of equipment, reducing unit energy consumption |

| 8,Easy to operate and maintain |

Product Categories : Corrugated Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.