Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Corrugated Line

Brand: LLY PACK

Applicable Industry: Manufacturing Plant

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Species: Corrugating Machine

Programming Control: Yes

Place Of Origin: China

Warranty Period: 2 Years

Productivity: 180 M/Min

Core Selling Point: Easy To Operate

Max. Feasible Width: 1100mm

Mechanical Test Report: Not Available

Video Factory Inspection: Not Available

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc

PLC Brand: Schneider, Siemens

Packaging: Case

Productivity: 50 set/year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 50sets/Year

Certificate: CE.ISO.TUV.SGS

HS Code: 8441

Port: Foshan,Shenzhen,Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA

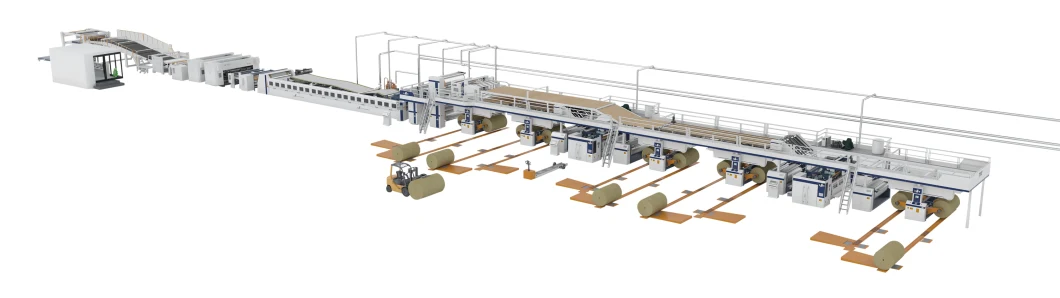

5 layer Corrugated Cardboard Production Line

Pit machine fully enclosed wallboard, high thickness casting base, large area positioning surface structure, size roller structure, oblique low center of gravity design, flip paste structure.

Soft contact structure of pressure roller and paste roller, quick change roller and easy adjustment.

Double-sided machine stack structure, three-point support structure, split drive main transmission.how is corrugated box made?

Pit machine cavity pipe core paper, pit arc plate, peripheral heating corrugating roller, cavity tube heat cylinder, double-sided machine cavity tubular inlet arc board, cavity tubular heat plate and steam hot plate.

Pit machine 4 sets of proportional valve control, double-sided machine 4 groups of proportional valves control, fine regulation of steam pressure, production line steam secondary use, return water pressure back to the boiler to achieve the third use of steam. Efficient utilization of the steam system.

High efficiency transmission chain design, such as direct connection, synchronous belt, precision gear, bevel gear, energy saving and efficient motor, closed-loop vector frequency conversion drive, etc.

High-precision structure of glue gap, electric cylinder drive to achieve precision adjustment gap, diaphragm pump for slurry system, automatic slurry system to achieve the glue of efficient non-destructive transport. The pit machine is equipped with a chiller as standard, which cools the hydraulic system and reduces the pulp basin temperature, thus preventing large amounts of low gelatinization temperature glue from setting

Raw Paper Roll Is Fed To The Roll Stand, After Heated And Moisture Adjusted By The Per-Heater, Raw Paper will Go To The Single Facer, Corrugated By lt, And Gluing Together With Another Raw Paper To Become Single Faced Corrugating Paper, Then Conveyed Through The Over Bridge, Re-Heated By Multi-Pre-Heater, After Glued By Glue Machine, Jointed By The Double Facer, Continuous Corrugating Board Comes Out.

After Slitting And Scorering By Slitter Scorer And Transverse Cutting By Cutoff, Corrugating Board With Different Sizes Are Produced. At Last, These Different Sizes Corrugating Board Will Be Stacked, Calculated And Then Send Out By The Stacker.

A Complete Corrugating Board Production Line Includes The Following Machines:

Mill Roll Stand, Pre-Heater, Splicer, Single Facer, Over Bridge, Heavy Duty Drive, And Glue Machine, Double Facer,Slitter Scorer, Cutoff, Stacker, And Ect.

| 1,Maximum mechanical speed:300m/min |

| 2,Production line width:1400~2800mm |

| 3,Positive pressure cassette type quick roll change single face corrugator |

| 4,Double motor upper and lower independent drive double-sided machine |

| 5,Equipment high stability, low noise, long life |

| 6,High physical index and high speed of cardboard |

| 7,Energy saving of equipment, reducing unit energy consumption |

| 8,Easy to operate and maintain |

Product Categories : Corrugated Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.