Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DS20

Brand: LLY PACK

Types Of: Packaging Line

Out-of-warranty Service: Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Status: New

Application: Machinery &Amp; Hardware

Type Of Packaging: Case, Cartons

Packaging Materials: Paper

Degree Of Automation: Automatic, Semi-Automatic

Warranty Period: 1 Year

Core Selling Point: Easy To Operate, Long Service Life, High Safety Level, Competitive Price, Sustainable, High Productivity, Multifunctional

Marketing Type: Ordinary Product, New Product 2020

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Condition: New

Driven Type: Electric

Warranty: One Year

After-sales Service Provided: Field Installation, Commissioning And Training

Certification: Iso

Marketing Type: Hot Product

Origin: China

Automation: Automatic

Trademark: Lly Pack

Transport Package: Plastic Film And Wooden Box

Place Of Origin: Guangdong, China

After-sales Service: Field Maintenance, Online Support

Model NO.: Ds20

After Warranty Servi: Video Technical Support, Online Support

Core Components: Plc, Motor, Other

Voltage: 380v,Customizable

Power: 30-39kw

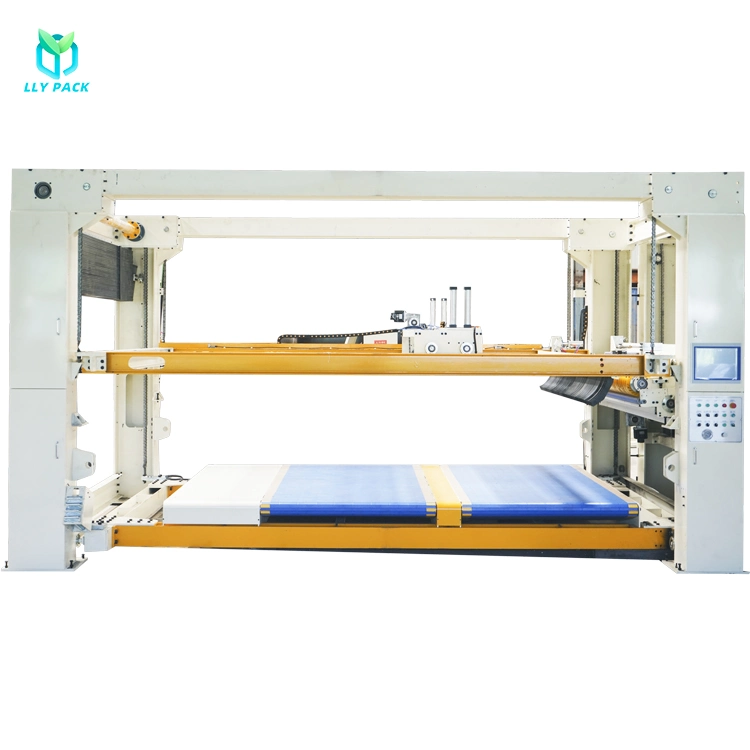

Product Name: Auto Stacker Machine

Paper Width: 1400mm-2300mm

Advantage: Long Service Life,Automatic

Function: Multi-Order Stacking Machine

Weight: 9000 Kg, 9-14t

Machinery Test Repo: Provided

Specification: 18500*3800*3500

Applicable Industrie: : Corrugated Cardboard Production Line

Packaging: Case

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 200 PCS/Year

Port: Foshan,Guangzhou,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

Corrugated Cardboard Production Line auto stacker

Automatic Stacker

1. The machine can be connected and communicate with the production management system to read order information and order changeover signal, so the separation is accurate and rapid for different orders; the machine can also operate in a stand-alone manner.

2. The feed-out rollers are driven by a frequency converter controlled frequency conversion motor, so the acceleration and deceleration are stable, the cardboard output is smooth, and it is not easy to make the cardboards turnover.

3. The lifting platform is driven by a frequency converter controlled brake motor and gravity

counterweights are installed, so the acceleration and deceleration are stable and forceful and the speed changeover is reasonable and effective; thus, the cardboard stacking is smoother, the folded marks on cardboards are avoided and the life of the machine is extended.

4. The feed-out rollers are arranged closely and are lifted together with the lifting platform to reduce waste paper sheets.

5. The sun gear for paper output is pneumatically controlled and the air circuit is specially

designed, so the paper output is stable and tidy.

6. The ascending arc of the conveyance platform is reasonable, so partial lifting, etc. of the cardboards will not occur during conveyance.

The machine has multi-order stacking function.

| Paper Width(mm) | External Dimensions (mm) L*W*H | Weight(T) | Total Power of Motor(kW) |

| 1400 | 18500*3800*3500 | 9 | 30 |

| 1600 | 18500*4000*3500 | 10 | 30 |

| 1800 | 18500*4200*3500 | 11 | 35 |

| 2000 | 18500*4400*3500 | 12 | 35 |

| 2200 | 18500*4600*3500 | 13 | 39 |

| 2300 | 18500*4700*3500 | 14 | 39 |

Product Categories : Corrugated Machine > Automatic Stacker

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.