Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DS20

Brand: LLY PACK

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: No Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Species: Corrugating Machine

Programming Control: No

Place Of Origin: China

Warranty Period: 2 Years

Productivity: 200 M/Min

Core Selling Point: High Productivity

Max. Feasible Width: 1200mm

Mechanical Test Report: Not Available

Video Factory Inspection: Not Available

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Motor

PLC Brand: Schneider, Siemens

Packaging: Case

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 200 PCS/Year

Port: Foshan,Guangzhou,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

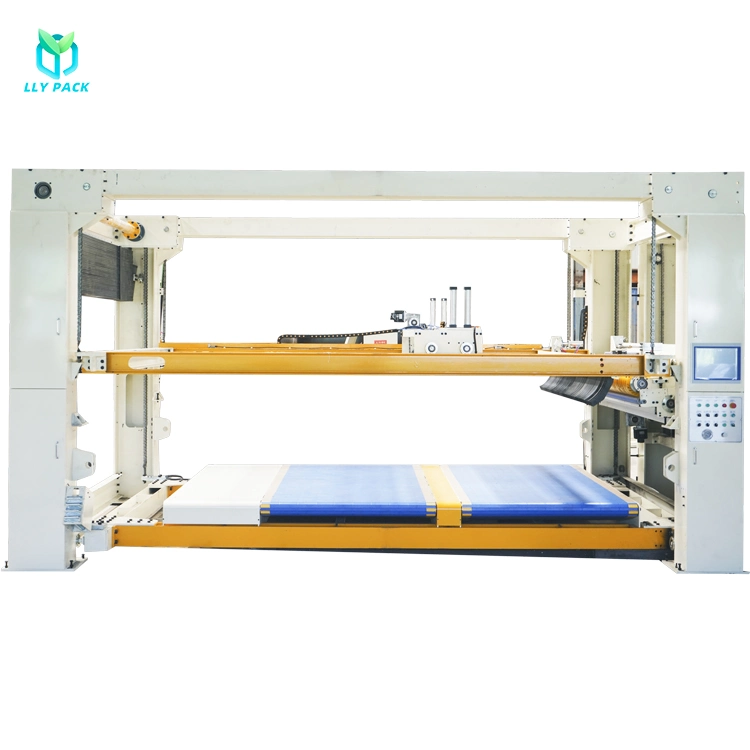

SPECIFICATION

The maximum paper collecting length: 3.5m.

The maximum paper stacking height: 1.8 m.

The conveyance device is divided into four sections; the first section is equipped with a strip pressing mechanism which makes the input cardboards be stacked in order. There is a paper ejecting rod between the first and second conveyor belts. The rod and the belts cooperate with each other and, under the control of an electrical system, synchronize the cooperation of different speeds in all sections and, if appropriate, lift the paper ejecting rod, so as to carry out accurate separation of cardboards by order/lot. Each section is driven by an AC frequency conversion motor, runs synchronously with the production line, and generates proper paper stacking ratio in conveyance according to paper length so that the paper sheets are stacked in order.

Automatic stacker Specification

| Paper Width(mm) | External Dimensions (mm) L*W*H | Weight(T) | Total Power of Motor(kW) |

| 1400 | 18500*3800*3500 | 9 | 30 |

| 1600 | 18500*4000*3500 | 10 | 30 |

| 1800 | 18500*4200*3500 | 11 | 35 |

| 2000 | 18500*4400*3500 | 12 | 35 |

| 2200 | 18500*4600*3500 | 13 | 39 |

| 2300 | 18500*4700*3500 | 14 | 39 |

1. The feed-out rollers are driven by a frequency converter controlled frequency conversion motor, so the acceleration and

deceleration are stable, the cardboard output is smooth, and it is not easy to make the cardboard turnover.

2. The lifting platform is driven by a frequency converter controlled brake motor and gravity counterweights are installed, so the acceleration and deceleration are stable and forceful and the speed changeover is reasonable and effective; thus, the cardboard stacking is smoother, the folded marks on cardboard are avoided and the life of the machine is extended.

3. The feed-out rollers are arranged closely and are lifted together with the lifting platform to reduce waste paper sheets.

4. The sun gear for paper output is pneumatically controlled and the air circuit is specially designed, so the paper output is

stable and tidy.

5. The ascending arc of the conveyance platform is reasonable, so partial lifting, etc. of the cardboard will not occur during

conveyance.

The Automatic Stacker is a versatile piece of machinery that greatly enhances efficiency in various industrial processes. The Automatic Paper Stacker specializes in organizing paper sheets with precision, while the Automatic Sheet Stacker handles a wider range of materials with equal dexterity. For the specific task of stacking corrugated cardboard, the Corrugated Cardboard Stacker offers a tailored solution that ensures both speed and accuracy. Each of these stackers, with their specialized functions, contribute significantly to the automation and optimization of stacking operations.

Product Categories : Corrugated Machine > Automatic Stacker

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.