Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: LLYPACK

Blade Length: 6 1/2in

Processing Type: High Frequency Welded

Warranty: 1 Years

Blade Thickness: 0.9~1.1mm

Teeth Per Inch: Customize

Teeths: Customize

Process Type: High Frequency Welded

Customized Support: Oem, Odm

Brand Name: Max Cut

Finishing: Ti-Coated

Size: Customize, 13*0.8*3P

Grade: Industrial

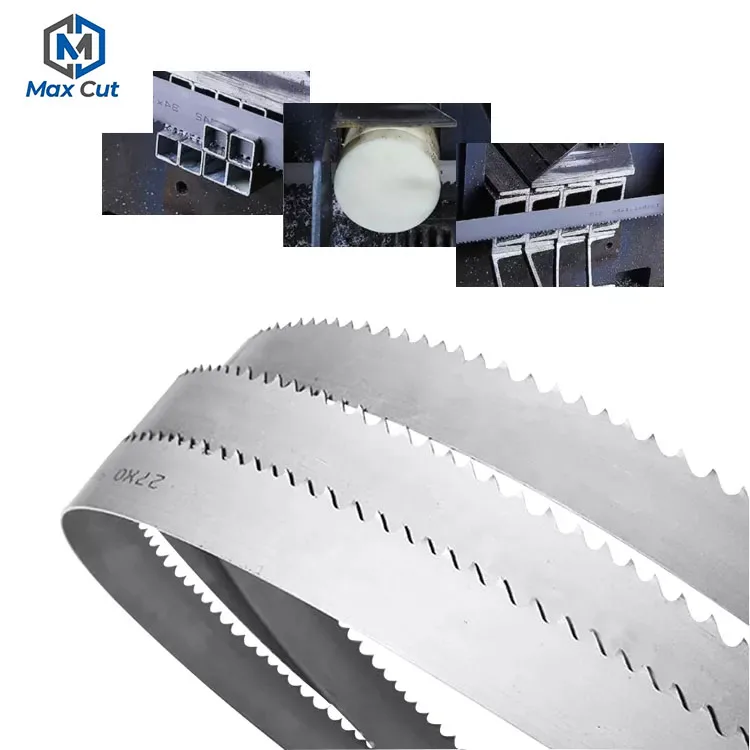

Product Name: Bi-metal Band Saw Blade

Application: Metal Cutting

Blade Material: HSS M35/M42/M51

MOQ: 1piece

Type: Power Tool Accessories

Advantage: Durable

HRC: 46-48

Tip HRC: 62

Blade Width: 19~41mm

Arbor Size: Customize

Place Of Origin: Guangdong, China

Packaging: Case

Supply Ability: 10000 Piece/Pieces per Month

Port: Shenzhen,Foshan,Guangzhou

Payment Type: L/C,Western Union,D/P,D/A,T/T

Key Benefits of Bi-Metal Band Saw Blades metal band saw blade

Longer Service Span: These blades require fewer replacements, offering a lasting service life.

Quieter Production: carbide steel band saw blade Advanced development techniques lead to reduced noise during cutting phases.

Enhanced Cutting Quality: Achieve better-looking cuts and superior performance due to the precise teeth setting.

Durable Construction: The high-speed steel edge delivers resilient cutting power, Slotting Saw Bladecomplemented by a tempered alloy backer for increased longevity.

| Product name | Bi-metal Band Saw Blade | | | ||

| Service | ODM&OEM | | | ||

| Material | HSS M35/M42/M51 | | | ||

| Material Cutting | Alloy steel/carbon steel/ Stainless steel/mold steel | | | ||

| Details | Preferred material、Serrated sharp | | | ||

| Width | Thickness | Tooth Pitch |

| 19mm | 0.9mm | 2/3TPI 3/4TPI 4/6TPI 5/8TPI |

| 27mm | 0.9mm | 2/3TPI 3/4TPI 4/6TPI 5/8TPI |

| 34mm | 1.1mm | 2/3TPI 3/4TPI 4/6TPI |

| 41mm | 1.3mm | 2/3TPI 3/4TPI 4/6TPI |

| 54mm | 1.6mm | 2/3TPI 3/4TPI 4/6TPI |

| 67mm | 1.6mm | 2/3TPI 3/4TPI 4/6TPI |

| 80mm | 1.6mm | 0.75/1.25 1.4/2 1/1.5 2/3 |

Carbide slitting saw blades, renowned for their exceptional durability and cutting precision, are a staple in advanced manufacturing processes alongside traditional saw blades and band saw blades. These carbide-tipped blades excel at swiftly slicing through tough materials like metals and alloys, making them ideal for intricate slitting operations that require both accuracy and speed. In contrast, general-purpose saw blades, while versatile, might not match the performance of carbide slitting saw blades in terms of longevity or precision under heavy-duty conditions. Meanwhile, band saw blades, with their continuous loop design, excel at long, straight cuts in a variety of materials, from wood to some metals, offering a distinct advantage in mass production settings. The integration of carbide slitting saw blades, saw blades, and band saw blades within a manufacturing workflow ensures a comprehensive range of cutting capabilities, allowing for the efficient and precise production of a wide array of components and products.

Product Categories : Industrial Cutting Blade > Metal Cutting Saw Blade

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.