Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

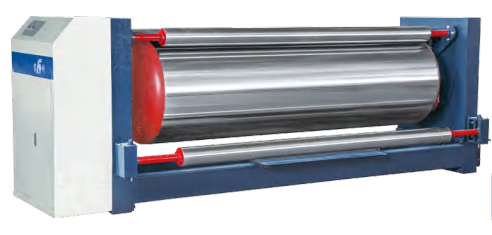

○ The diameter of the pre-heating cylinder: φ1,028 mm/φ828 mm; the pre-heating cylinder meets the China national standard for Class 1 pressure vessels; With the pressure vessels test certificate.

○ The cylinder body has an elliptic end plate structure to offer even heating of raw paper.

○ A chain transmission is hidden in the wall of the machine, so it is safe and reliable;

○ Paper guide rollers: One direction-changing roller is fixed on the wall of the machine and another one is mobile outside the pre-heating cylinder to control the heating area of the face paper; the parallelism of the mobile paper guide roller is adjustable.

○ The direction-changing roller of the core paper pre-heating cylinder has an elastic roller structure, offering even tension of raw paper.

○ The angle of contact is adjustable in approximately 360°.

○ The rotation surface can be properly adjusted according to the wear situation of the pre-heating cylinder.

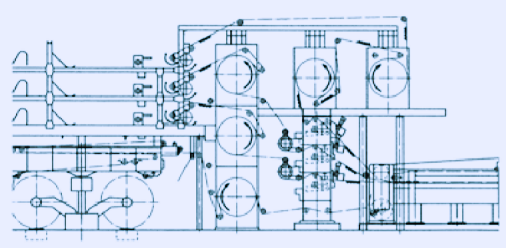

A corrugator line should be equipped with multiple preheaters, both single cylinder preheater and multiple preheater. Among them:

Medium quality control cylinder -- Before the paper feeding into the Single Facer, plus steam spraying equipment;

Liner preheater -- To adjust the angle-wrap of paper web before the paper enters the single facer;

Multiple preheater -- To heat single corrugator and linerboard before the paper web is fed into the double-sided machine.

In the production process of three-layer and five-layer corrugated board, if there is a problem of applying glue, the solution is: through the other direction into the preheater for reverse preheating, that is, to heat the other side of the paper and reverse removal of paper moisture.#Pre-heating Cylinder Pneumatic cylinders

Usually, a three-layer cardboard production line (one set of single facer) should be equipped with two preheater groups, and a five-layer cardboard production line (two sets of single facer) pneumatic air cylinder should be equipped with three preheater groups.If a single facer needs to run a large amount of heavy kraft paper at high speed (more than 350 grams/square meters), equipped with three preheater groups will also play a good role.Seven-layer board production line, heavy duty corrugated board production line can have up to five preheater groups, so that the angle-wrap is more diversified.#Corrugated Line

▲Seven-layer board production line, heavy duty corrugated board production line can have up to five preheater groups,

so that the angle-wrap is more diversified.

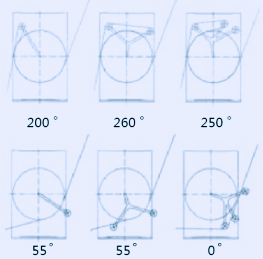

On the preheater, the aller the angle between the angle-wrap adjusting roll and the paper guide roll, the aller the contact area between the paper width and the drum dryer;The larger the angle between the angle-wrap regulating roll corrugated slitter and the paper guide roll, the larger the contact area between the paper width and the drum dryer.Because the preheater to balance the humidity and moisture content of the base paper, to ensure the ooth production of cardboard, so the preheater has to maximize the angle-wrap adjustment, in order to timely change the heating area of paper web on the drum dryer.#Preheater

▲Comparison diagram of wrap control system

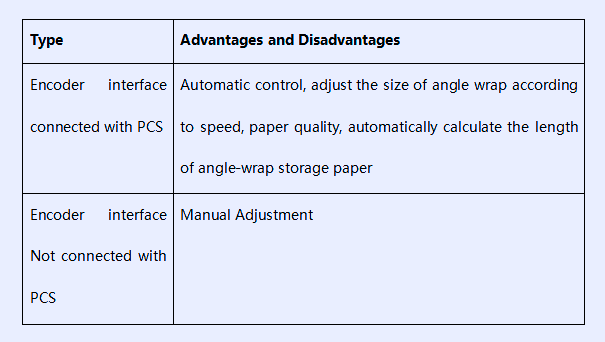

If the preheater has an encoder interface connected to the production pipe, it can automatically control the angle-wrap -- the angle-wrap can be automatically adjusted according to the speed and paper quality, and the length of angle wrap can be calculated automatically.

If the preheater does not have an encoder interface to the pipe, the operator manually adjust the angle-wrap.Depending on the operator's personal experience to adjust the size of the angle-wrap is very easy to cause the paper web too wet or too dry, resulting in the production quality of the subsequent process.#Preconditioner

Table 1:Comparative analysis on advantages and disadvantages of angle-wrap control system

In addition, the current drum dryer of preheated in the market is generally fixed.But equipment suppliers have also developed more advanced configurations that allow the durm dryer to rotate.If the preheater drum dryer can rotate, the surface area of the drum dryer in contact with the paper will no longer be fixed, which is conducive to the uniform use of steam in the drum dryer, on the other hand, it can be more energy saving.

*Statement: the purpose of this article is to convey market information more widely, and the content of the article is for reference only. The copyright of this article belongs to the original author and the original source, the content is the author's personal point of view, does not mean that the site agrees with its point of view and is responsible for its authenticity, this site only provides reference and does not constitute any investment and application suggestions. Some articles on the website of this site are reprinted and are not used for any commercial purposes. We have notified the author and source as far as possible. If there is any omission of relevant information or inappropriateness, please contact us in a timely manner. We will immediately correct or delete the relevant content according to the requirements of the copyright owner. This site has the right of final interpretation of this statement.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.